Lathe and Turning Center

location:homePRODUCT > Machine Host > Lathe and Turning Center >

-

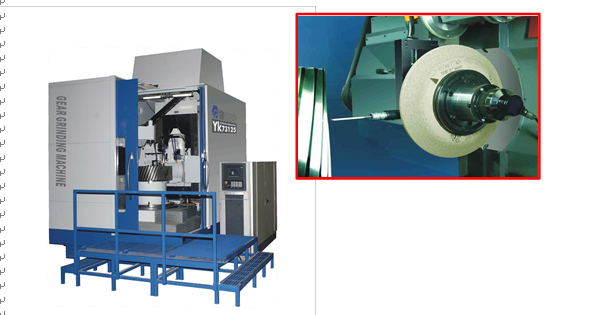

QC YK73125 Vertical CNC Profile/Form Gear Grinding Machine

6.0 Machine WarrantyThe #73125 is the next larger brother to the proven and popular #7380. With a greater number of installations than the #7380 in the field, the #73125 utilizes the exact same grinding head with a larger capacity base, enclosure and workholding area for external form grinding. Featuring a 20KW (27 HP) grinding spindle and a capacity of 1250,0mm tip diameter (50”), 600,0mm (24”) face width capability, the #73125 also utilizes the same software, on-board inspection capability and PC-Based NUM controls package as its smaller brother. The #73125 is actually flexible enough that a 1500,0mm workpiece (60”) will fit in a pinch; and this does provide some insight into how flexible this machine platform really is. With identical features to its smaller relative, the #73125 comes standard with inspection measurement and printing capability featuring Renishaw equipment.

The working principle of this machine is form grinding. The profile of the grinding wheel is modified via on an on-board wheel dressing system and software package designed with a graphical interface to simplify complex profiling requirements.

Main Characteristics

· Compact machine design featuring a ribbed, one-piece cast iron bed.

· Column, carriage and workpiece table utilize a constant flow hydrostatic guideway system.

· Ergonomic design with complete machine access from the ground floor and through a well designed and completely lit enclosure.

· Flexible workholding area to accommodate all manner of customer workpieces up to 1350,0mm in height (53.15”).

· The on-board automatic dressing cycle of the grinding wheel improves the uptime and efficiency of this machine tool. Using customized QC Software with a conversational format, profiles of the grinding wheel are easily modified.

· NUM (Swiss Made – USA Serviced) 1050H PC Based CNC control with eight (8) independent axes of control.

· Integrated Schmitt Industries (SBS – USA) dynamic grinding wheel balancing system for greater control of the grinding and dressing process.

· The special Human Machine Interface (HMI) was developed by QC according to the working characteristics of North American gear processing. Based on a conversational programming protocol,

programming is simplified by entering work piece parameters and relevant technical parameters as called out by the operator.

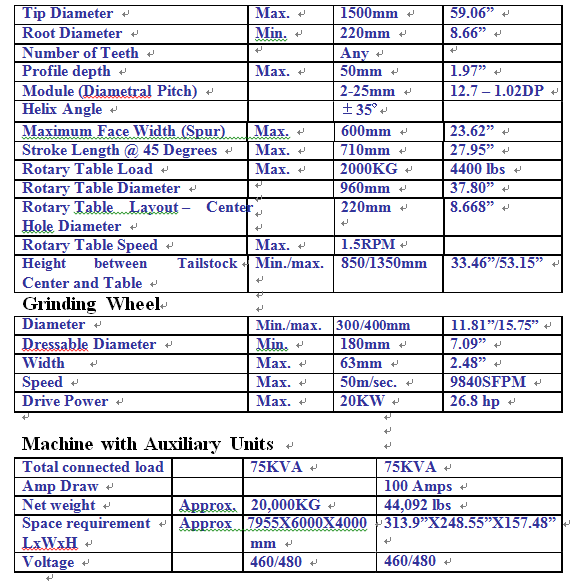

Technical Data

1. Base Machine

1.1 Assembly Groups

· Machine Base of a ribbed cast iron design; carries the column, rotary table and outer column. Installation on leveling/vibration isolation pads.

· Column made of cast iron with constant flow hydrostatic guide ways. Radial infeed using precision ball screw, powered directly by an AC servo motor.

· Rotary table with constant flow hydrostatic bearing. Driven by AC servo motor through backlash free worm wheel.

· Stroke slide with constant flow hydrostatic guide ways. Stroke motion through precision ball screw, powered directly by an AC servo motor.

· Grinding slide with tangential movement using precision ball screw, powered directly by an AC servo motor.

· Grinding spindle is a direct drive high-speed spindle.

· CNC dressing device is a stationary unit for dressing grinding wheels with dressing spindle and diamond dressing wheels. The dressing paths are generated by the vertical and the tangential grinding slide movement.

· Outer column for clamping pinions between centers. Tailstock height adjusted through a screw and nut assembly.

1.2 Electrical Equipment

1.2.1 Power Supply

Operating voltage is 460/480 Volt/3Phase/60Hz.

1.2.2 Operator Interface Features: NUM Power 1050 Axium

CNC Control

· Operator station with TFT color flat screen and control panel in front of the control cabinet. Integrated keyboard with a team of horizontal and vertical soft keys.

· Hand-held operating panel for more convenient set-up of the machine.

· The machining program uses standard CNC conversational programming language fully developed by QC, and the interface program uses NUM standard MMI TOOL software.

· Swiss-owned NUM is serviced out of Naperville, IL. QC American provides front-line service regardless.

Control Interface Features

· Windows XP Professional Operating System

· 586MB Pentium processor

· 30GB hard drive

· 128M RAM

· 56K modem

· Two USB Ports for archiving user and machine data.

· 3.5” floppy drive.

· Parallel interface for connecting a printer.

· Serial interface for common use.

· Ethernet interface.

Service Functions

· Integrated modem and ethernet ports for remote diagnostics connection between QC computers.

· Graphical display of processing data.

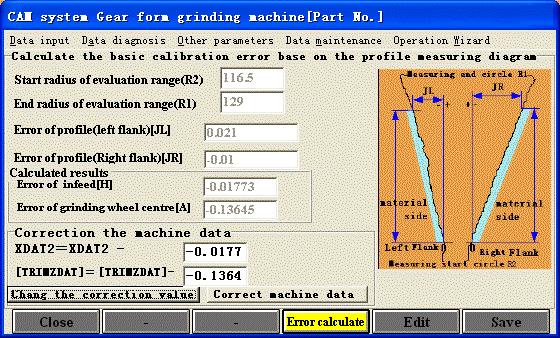

1.3 Software for PC Based NUM Axium Power 1050H Control

This QC Developed software package enables the user to generate, edit and optimize grinding programs and analyze processing data on the PC on the machine or a remote PC. The software interface is identical with the machine control menu and may even be used for rudimentary training purposes.

· Gear parameters calculation module – Input and storage of workpiece data. This module consists of a conversational interface for geometrical parameter data entry, technical parameters and measuring parameters to facilitate computing of standard gears, gears with addendum modification,

modified spur (helical) cylindrical gears. Basic work piece data is recorded into a database for later

editing or processing.

· Profile computing module for grinding wheel – Profile and Lead modification. This module serves to gather data in order to generate the correct wheel profile through an editable series of dressing cycles using the on-board dressing wheel system. Based on data entered about the workpiece

and special requirements on gears to be machined; including profile, lead modification and fillet curve parameters, the profile of the grinding wheel can be automatically computed to meet the task at hand.

· Conversational Control Design. The G code will be automatically created based on the gear processing and grinding parameters entered by the user. In addition, the customers can even directly use and upload straight G code if desired.

· Customer can add specific modifications to suit their applications.

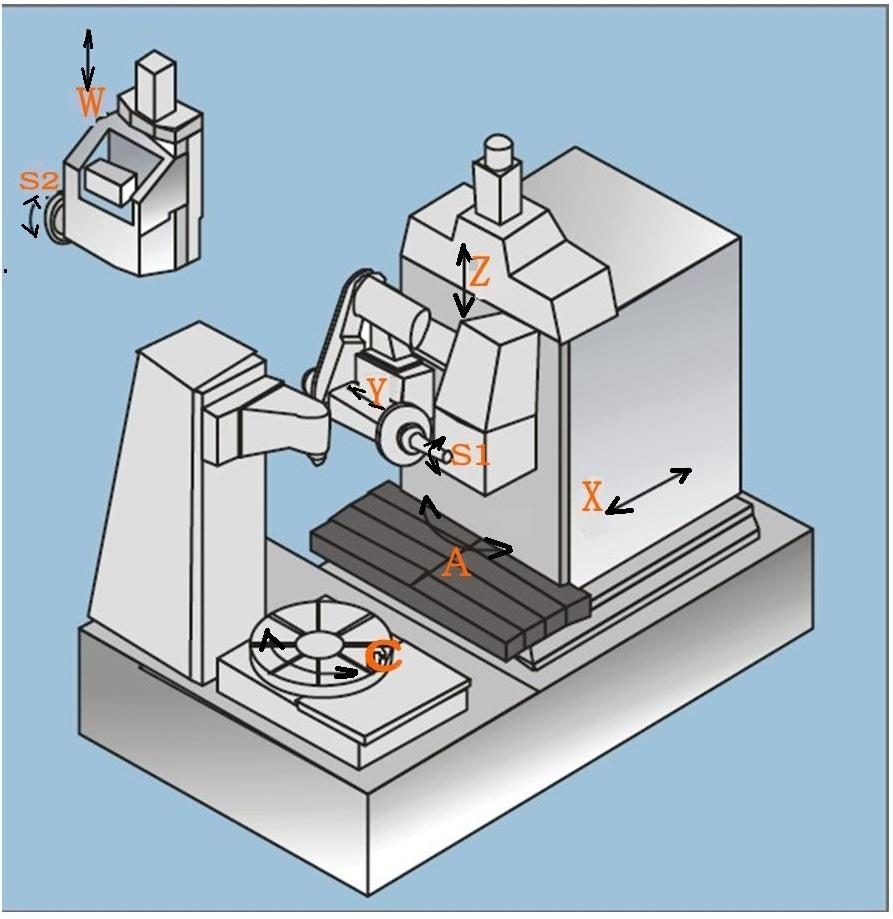

1.4 Axis Information

Eight (8) CNC Controlled-Axes

· ‘X’-Axis. Radial (feed) movement of the column. Constant Flow Hydrostatic Guideway. AC Servo motor with precision ball screw.

· ‘Z’-Axis. Axial (vertical) movement of the grinding stroke slide. Constant Flow Hydrostatic Guideway. AC Servo motor with precision ball screw.

· ‘Y’-Axis. Tangential (horizontal) movement of the grinding slide. Schneeberger Needle Type Linear guideway. AC Servo motor with precision ball screw.

· ‘A’-Axis. Rotary movement of grinding wheel head for grinding helix angles. Rotary positioning encoder – Heidenhain.

· ‘C’-Axis. Indexing and rotary movement of the rotary table. Constant Flow Hydrostatic Guideway. Heidenhain +/-0,001mm Resolution.

· ‘W’-Axis. Dressing axis of grinding wheel. Schneeberger Needle-Type Linear guideway.

· ‘S1’-Axis. Rotation of grinding wheel.

· ‘S2’-Axis. Rotation of diamond dresser wheel.

All CNC axes utilize closed-loop controls. The positioning feedback devices of each axis utilize HEIDENHAIN high precision encoders and scales.

1.5 On-Board, Integrated Measuring System (Option)获取更多信息

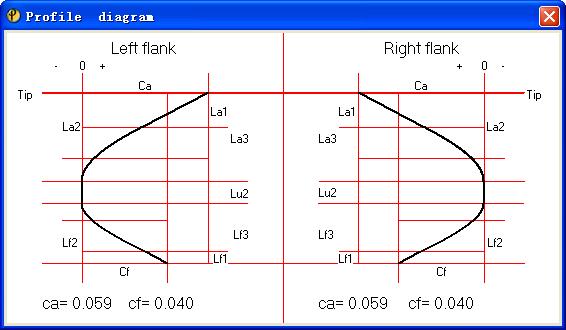

The machine can be equipped with a Renishaw measuring system on-board the machine. Including the #LP-2 measuring probe, cables, adapter card and a QC software integration module. It is very easy to connect with your printer through one of the USB ports on the control. You can store or print measurement reports at any time. Based on the measuring data, the on-board inspection system can draw out a diagram of profile, lead,pitch, cumulative pitch of gear tooth and print and/or store the measuring data to allow for analysis of the previous grind cycle’s effect on the workpiece. The program can automatically analyze and judge the measuring results, correct the machine parameters and the profile data of the grinding wheel.

This system has long been perfected on the #YK7380 & #YK73125 machines. There is an electrically operated moveable arm carrying the measuring probe. The arm automatically rotates as the machine moves to the measuring position, which is located close to the grinding wheel. See picture, on page 1.

2.0 Peripherals

2.1 Hydraulics/Lubrication

Complete hydraulic system for lubrication, clamping, and tailstock stroke.

2.2 Hydrostatic System

Complete constant flow hydrostatic system for ‘X’, ‘Z’ and ‘C’ Axes.

2.2 Coolant Filtration System

The coolant filtration system cleans used coolant using paper filtration media and

includes the following:

· Temperature controlled for grinding fluid utilizing a chiller–type oil cooler.

· Filter capacity=120L/min.

· Multiple circuit coolant chilling equipment: With automatic temperature regulation for cooling oil.

· Oil mist recovery and electrostatic air filter system.

3.0 Standard Machine Accessories

4.1 Machine Color

Machine and peripheral units: Blue

Doors: White

4.2 Power-off Protection System

For controlled retreat of the machine into a safety parking position in case of a power outage to protect workpiece and tools. Included.

4.3 Operator Training at Customer Facility

Our program is designed to prepare your operators to begin operating the machine directly before or after final acceptance at your facility.

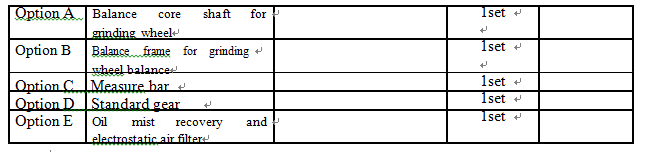

5.0 Special Accessories (Options)

6.0 Machine Warranty

A warranty period of 12 months on entire machine and accessories from time of final acceptance or 5,000 hours of use – whichever occurs first. An extended warranty is available per further negotiation(s).

7.0 Spare Parts Warranty

Spare Parts availability is guaranteed for 10 years from the date of machine commissioning with deliveries under current market conditions.